Photos détaillées

Performance

spécification

| Dimension Of block making machine | 3600×1800×2600mm | Motor Power | 29.4KW |

| Mould Area | 550×900mm | Vibration Force | 40KN |

| Working cycle | 15-18S | Concrete mixer model | JS500 |

| The Size Of The Pallet | 900×550×30mm | Weight Of The block making machine | 6000kgs |

| Size(LxWxH) | Pcs/Mould | Pcs/ Hr | Pcs/ 8 Hr |

| 400X100X200 | 8 | 1200-1920 | 9600-15360 |

| 400X150X200 | 6 | 900-1440 | 7200-11520 |

| 400X200X200 | 4 | 600-960 | 4800-7680 |

| 400X250X200 | 3 | 450-720 | 3600-5760 |

| 200X100X60 | 16 | 1920 | 15360 |

| 200X163X60 | 8 | 1200 | 9600 |

| We can provide different sizes mould as you request. | |||

1. Cement silo and screw conveyor: The cement silo is used to store the bulk cement which is used for concrete. The screw conveyor is connect with the cement silo and concrete mixer to transfer the cement into the concrete mixer. These two parts are optional parts. You can get them at local market or purchase them from us together with our block making machine;

2. Aggregate batching machine: It consists of two or three storage bins and one weighing bin. It also contains belt conveyers which is used to convey aggregate and sand from the storage bins to weighing bin. Batching and weighing is controlled by PLC.

3. Concrete Mixer: All the ingredients are mixed in this concrete mixer. Mixing time and speed is controlled by PLC. The water pump which is controlled by time relay adds water to the mixer automatically;

4. Belt conveyor: after the concrete is ready, it will be discharged to this belt conveyor, the belt conveyor will transfer the concrete to the concrete block machine;

5. Block making machine: This is key part of the production line. It presses the concrete to block. It can be used to make various hollow block, solid brick, paver brick and kerbstone by changing different sizes moulds;

6. Stacker: Stacker is used to stack the blocks automatically, which is high-efficient and labor saving.

7. After the above procedures, the blocks will be transported to the storage yard for drying.

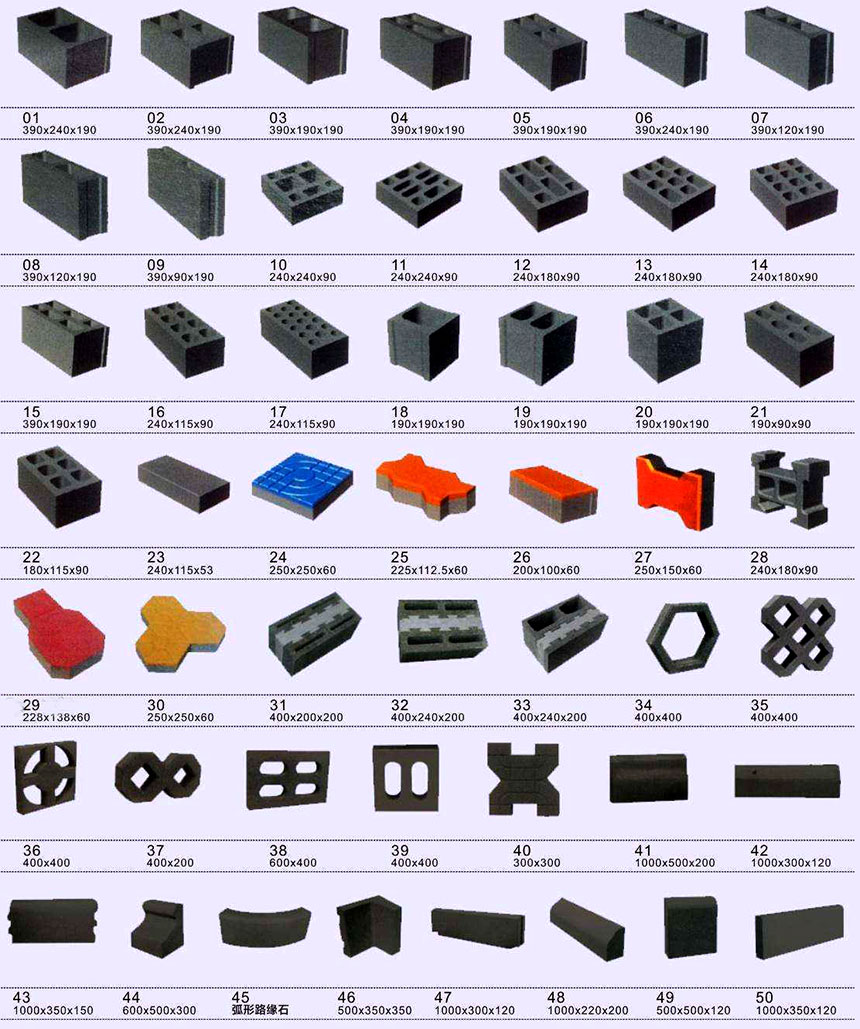

4. Block and Brick Models:

Tags: machine de fabrication de blocs de porcelaine au Burundiprix de la machine de fabrication de briques en béton au Burundimachine de fabrication de briques simples au Burundimachine de fabrication de blocs creux en béton au Cap-Vert mobile concrete batch plant in Djiboutichenilles pour mini-chargeuse à roues en Zambiebrick making in Sierra Leone,portable concrete batch plant for sale in Uganda

Solutions

Machine de fabrication de blocs

Machine de fabrication de blocs QT5-20

Usine de fabrication de blocs automatique QT4-15

Usine de fabrication de blocs automatique QT6-15

Usine de fabrication de blocs automatique QT8-15

Usine de fabrication de blocs automatique QT10-15

Machine de fabrication de blocs QT4-20

Machine de fabrication de blocs QT5-20

Matériel

Bétonnières

Centrale à béton

Usine de transport de béton

- Pompe à béton série HBT / DHBT

- Pompe à béton montée sur camion

- Pompe à béton-montée sur camion

- Flèche de placement de béton hydraulique mobile

- Flèche de mise en place de béton hydraulique

- Bétonnière sur camion

- Pompe à béton XBS / DXBS pour pierres fines

- Camion malaxeur à béton

- Bétonnière 6cbm

- Flèche de mise en place manuelle du béton

Équipement de béton connexe

Usine de fabrication de blocs de béton

NOUVELLES

- Bétonnière DHBT15 avec pompe a commencé à fonctionner

- Une bétonnière autochargeante de 2m3 a été livrée en Asie du Sud

- Nous avons livré un ensemble de pièces de rechange de chariot élévateur en Indonésie

- Nous avons livré deux ensembles de pièces détachées de pompe à béton DHBT40 au Cameroun

- Deux centrales à béton HZS25 et une machine à blocs de béton QT4-15 ont été livrées à notre client

- Bétonnière autochargeante HAMAC HMC400 livrée aux Tonga

- Reliable Performance of HZS120 Concrete Batching Plant

- An Independent Off-road Mobile Batching Plant

- How to buy cost-effective concrete batching plant

Obtenez un devis

Obtenez un devis Bavarder

Bavarder